Contents

1 Introduction

The Control of Substances Hazardous to Health Regulations (COSHH) 2002 (as amended) provide a legal framework for preventing the exposure of persons to hazardous substances arising from work activities. Where this is not possible, exposure must be minimised to levels that are as low as reasonably practicable, and to below statutory maximum workplace exposure limits (WELs). A WEL is the maximum concentration of an airborne substance, averaged over a reference period, to which an employee may be exposed by inhalation. These substances can also be identified by their warning labels (see section 5.1).

Hazardous substances are materials or mixtures of compounds that may cause potential harm to health if they enter the body via various routes, including inhalation, absorption through the skin, ingestion or through contact with the eyes. Substances hazardous to health can occur in many forms, for example, solids, liquids, vapours, gases, dusts, fibres, fumes, mist and smoke. They can also be biological agents such as pathogens or cell cultures and can be carried in bodily fluids.

The regulations require the employer to identify all hazardous or potentially hazardous substances that may be used in the workplace or that may be produced by a work process. The employer must then conduct an assessment of these substances, evaluating the risk of exposure of people and, where necessary, take the appropriate precautions to prevent or control that exposure.

2 Purpose

The purpose of this policy is to set out the trust arrangements to comply with the COSHH regulations, with the aim of preventing injuries and reducing acute or chronic ill health at work. The trust will take reasonable steps to prevent exposure to hazardous substances, or, where this cannot be prevented, to reduce exposures to acceptable levels.

3 Scope

The policy applies to all employees, volunteers and contractors working within any buildings under the control of the trust.

COSHH does not apply to the following:

- asbestos and lead, which have their own regulations.

- substances which are hazardous to health only because they:

-

- are radioactive

- are at high pressure

- are at extreme temperatures

- have explosive or flammable properties (other regulations apply)

- biological agents that are outside the employer’s control, for example, acquiring a healthcare associated infection

- medicines, as these substances are covered under the medicines management policy

Reference should be made to the personal protective equipment (PPE) policy as PPE may be required as an additional control measure to control exposure to hazardous substances.

4 Responsibilities, accountabilities and duties

4.1 Chief executive

The chief executive has specific accountability to ensure that responsibilities for health and safety, including the management of hazardous substances are effectively assigned, accepted and managed at all levels in the trust consistent with good practice. This duty is delegated to others within the trust.

4.2 Executive directors

Executive directors have delegated responsibility for the management of health and safety, including ensuring that there are suitable and sufficient arrangements and resources for minimising exposure to hazardous work substances and to ensure this policy is implemented throughout the trust. This is further delegated to managers and supervisors.

4.3 Health and safety lead or health and safety team

The health and safety lead will provide advice on the completion of COSHH assessments and any other relevant statutory provisions required. The health and safety lead may be assisted by other members of the Health and Safety team.

4.4 Managers or supervisors

Managers and supervisors have delegated responsibility for implementing the policy within their departments. This includes but is not limited to:

- bringing this policy to the attention of employees within their area of responsibility

- compiling an inventory of hazardous substances

- ensuring that COSHH assessments are carried out in their area of responsibility and are accessible to employees using the hazardous substances to which they relate

- ensuring that employees have appropriate information, instruction and training before using hazardous substances and are familiar with how to use any control measures

- selecting the correct type and specification of PPE where the risk assessment indicates that it is needed. The correct type and specification should be made using manufacturers guidance. Further guidance about the selection and use of PPE can be found in the PPE policy

- carrying out or arranging appropriate exposure monitoring and, or health surveillance where required. Further information is provided in section 5

4.5 Employees

All trust employees are responsible for ensuring that they take reasonable care of the health and safety of themselves and any other persons who may be affected by their acts or omissions at work. This includes raising any issues of concern relating to the safe use of hazardous substances, control measures or PPE.

They must be familiar with health and safety policies and procedures in particular in relation to substances in use at work including:

- the risks

- the controls, including making full and proper use of all engineering controls or safe systems of work. PPE should be used where indicated

- what to do in an emergency

- the results of any monitoring

- where the COSHH assessment documents are kept

- if health surveillance is indicated staff must attend

5 Procedure or implementation

In order to comply with the requirements of the COSHH Regulations the trust must:

- carry out risk assessments

- prevent or control exposure to hazardous substances

- identify and select suitable control measures

- provide information and training in the use of controls

- ensure that there are arrangements to deal with accidents and emergencies

- carry out exposure monitoring where required

- carry out health surveillance where appropriate

5.1 COSHH assessment

A COSHH assessment should identify the hazards and risks associated with the use of substances. It will also contain details of precautions to be taken to control the risks associated with their use. The trust COSHH assessment Form must be completed for all substances in use (see appendix B). The form together with the product or material safety data sheet (PSDS or MSDS) should be retained in a suitable file or designated computer-based folder.

A suitable record of all COSHH assessments must be kept locally in all departments. These should be reviewed on a regular basis (annually is recommended) and a management system should be established which allows for the periodic review of assessments.

Special consideration should be given to pregnant employees or those with disabilities who may be at additional risk from exposure to hazardous substances. Work with some chemicals, such as those that are known or suspected to cause birth defects should be avoided by pregnant workers.

The COSHH assessment process is as follows:

5.1.1 Identify which substances are hazardous

- Compile a list of the substances used in a particular area. This will create an inventory.

- Obtain PSDS or MSDS from product suppliers.

- Identify from the data sheets which substances are hazardous and why. Consider whether the substance will be in the form of liquid, gas, dust, fume or mist. The data sheets will provide information about the type of hazard in the form of hazard symbols as required by the European classification, labelling and packaging of substances (CLP) regulation (figure 1). If the substance has been assigned a safe workplace exposure limit (WEL) in the HSE’S EH40 document this will also indicate that a substance is hazardous in nature.

- Include biological hazards such as bodily fluids (for example, Blood, vomit, urine).

- Include substances created by the process, including waste products.

5.1.1.1 CLP symbols

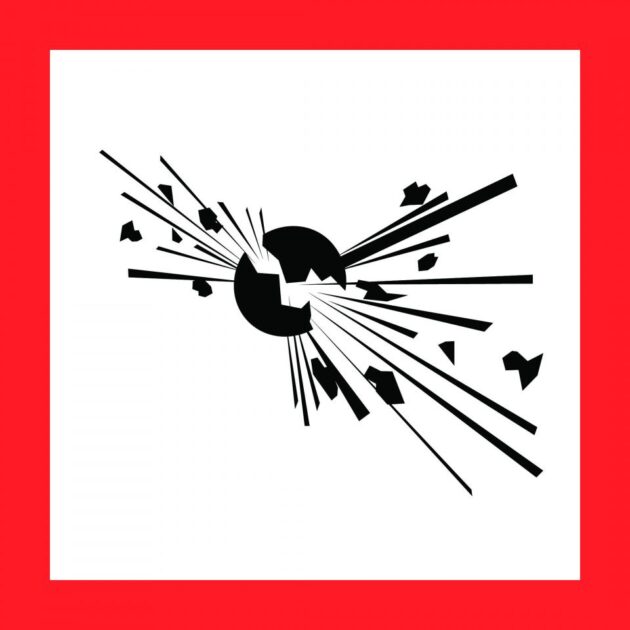

5.1.1.1.1 Explosive

5.1.1.1.2 Flammable

5.1.1.1.3 Oxidising

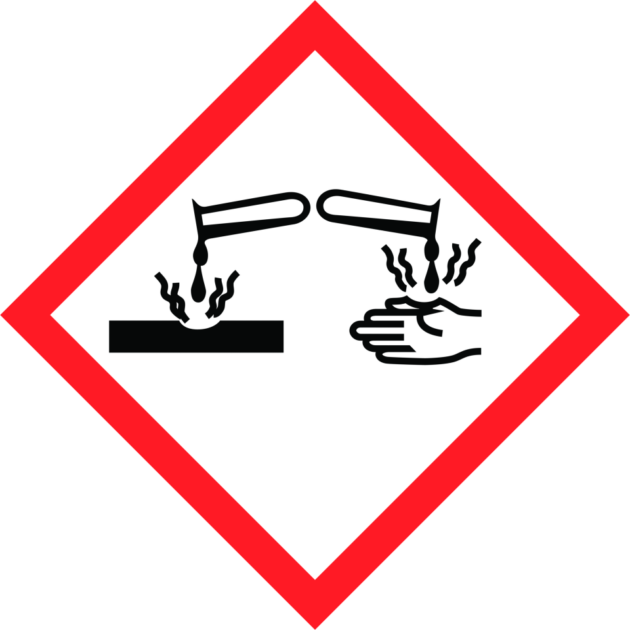

5.1.1.1.4 Corrosive

5.1.1.1.5 Toxic

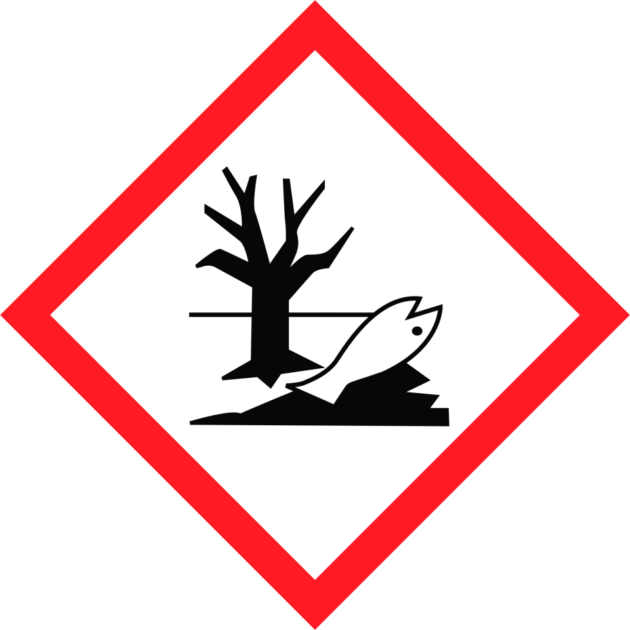

5.1.1.1.6 Environmental hazard

5.1.1.1.7 Harmful

5.1.1.1.8 Health hazard

5.1.2 Decide who might be harmed and how

- Consider who might be exposed to the substance and for how long. This will include employees working directly with the substance, ancillary staff working in the area, such as cleaners and maintenance employees, as well as contractors or visitors who pass near to or enter the work area.

- Examine work activities and work out what substances an employee may be exposed to, how often and for how long.

- A separate risk assessment should be carried out for groups of employees who may be at increased risk, such as pregnant workers, young people under the age of 18 and members of staff with increased susceptibility due to allergies or health conditions. g. asthma or dermatitis.

5.1.3 Prevent or control exposure

The main aim is to prevent exposure to hazardous substances, but where this not possible or practicable the trust should adequately control exposure. The priority for addressing exposure is based on the level of risk. This should take into account how hazardous the substance is, how often individuals are exposed and for how long. Substances with low short-term exposure limits, based on 15 minutes of exposure that are identified in the EH40 document generally have a more rapid or serious impact on health than those with a higher exposure limit.

The COSHH regulations advocate a hierarchy of controls that must be considered in the following order:

Prevent exposure

- Elimination, the COSHH regulations state that the most effective method of preventing exposure to hazardous substances is not to use the substance or to eliminate the production of hazardous waste or by-products. This could be achieved by changing or modifying the method of working so that the process causing exposure is not required.

- Substitution, if the process cannot be eliminated could an alternative less hazardous substance be used instead? If not, could the same substance be used in a different form? For example, could a solid be used instead of a liquid, or could pellets be used instead of a powder? These actions are a good step towards reducing exposure.

Caution should be exercised when selecting alternative substances and any decision should be based on a balance between the existing and any newly created risks. For example, a new substance with a lower level of toxicity but increased flammability might be a greater risk than the original substance.

Control exposure

- Engineering controls and work processes, this would include using processes that minimise the amount of the substance used or produced or equipment that totally encloses the process. Engineering controls separate the individual from the process. Exposure can be minimised by controlling hazardous substances at their source, rather than once they have been dispersed into the workplace. For example, local exhaust ventilation (LEV) may be used to control airborne contaminants.

- Worker specific controls: These controls include the use of PPE such as protective clothing, face masks and respirators and limiting worker exposure by job rotation. Although a risk assessment may identify PPE as being necessary, other means of control should be given preference, and wherever possible, PPE must not be relied upon as the only means of protection. It is too user-dependent to be fully reliable and only protects the user.

- Administrative controls: These include safe operating procedures, access permits, training and supervision. These are essential controls that do not sit in isolation, but are used in combination with other controls. Employees must be provided with information about the hazards and risks associated with their work, and about the means of controlling those risks. Inexperienced employees may require close supervision to ensure that they understand the risks and the need for the controls (and how to use them). The level of supervision is a risk control which should be determined by the local manager.

Under the COSHH regulations, exposure to a hazardous substance will be considered to be adequately controlled if all of the following are in place:

- the eight principles of good practice set out in schedule 2A to COSHH are applied (see appendix A)

- the workplace exposure limit for the substance (if there is one) is not exceeded

- if the substance is known to cause cancer (carcinogen), heritable genetic damage (mutagens) or asthma, exposure is reduced to as low a level as is reasonably practicable

5.1.4 Provide information and training

Employees must be made aware of the risks associated with any hazardous substances they use at work and how to use the controls put in place to reduce the risk of exposure. These include access to the COSHH assessment, information about the risks, the controls and how to use them, including how to use any PPE supplied for use during a work process.

5.1.5 Arrangements for dealing with accidents and emergencies

The PSDS or MSDS will provide information about suitable first aid responses for contact with the substance, any fire hazards and fire-fighting measures and how to deal safely with an emergency situation, such as a spillage.

5.1.6 Exposure monitoring

Monitoring is a means of establishing what concentration of a hazardous substance an employee may be exposed to whilst performing a work activity using that substance. It can also be used to determine how well the control measures are working.

Monitoring may be required:

- if there is any doubt that adequate exposure is being maintained. g. If there is a change in the system of work or an increase in the amount of the substance used

- as a check on the efficiency of the control measures, particularly where there is a WEL specified in the HSE EH40 document

Anyone appointed to carry out monitoring must be suitably trained and competent in monitoring techniques, such as membership of the British occupational hygiene society (BOHS).

Records of the monitoring should be kept. Where the exposure data contains details of a named employee, the record must be kept for a period of at least 40 years.

5.1.7 Health surveillance

Health surveillance is carrying out health checks on employees in order to detect any adverse health effects at an early stage. This will allow action to be taken to prevent more serious disease from developing.

Health surveillance may be appropriate in the following cases, for example, however this list is not exhaustive:

- where PPE is relied on as the main type of control measure

- there have been previous cases of work-related ill health

- where there is evidence of ill-health in the industry

A recommendation for health surveillance may be made following a referral to occupational health.

5.2 Therapeutic agents and biologically contaminated material

Cytotoxic drugs have been identified by the department of health as one of the six groups of materials which should be regarded as a priority for management review and effective control. Similarly, pathogens are formally defined as ‘hazardous substances’ under COSHH. Legionella bacteria, which may multiply in hot and cold water systems is also classified as a hazardous substance. The HSE approved code of practice and guidance, legionnaires disease, The control of legionella bacteria in water systems (L8) gives guidance in relation to the COSHH regulations. Details of the trust’s arrangements around the control of legionella can be found in the water safety policy.

5.3 Generic assessments

Appendix C explains the method of allocating substances into generic categories.

6 Training implications

Managers may require training in the completion of COSHH assessments. However, the COSHH assessment form is simple to use in conjunction with the guidance notes (appendix B). Completion and review of assessments will also identify training needs.

In house training about the safe use of cleaning solutions is provided at induction to employees in the Facilities Department and information is provided in work areas, such as sluices.

7 Monitoring arrangements

7.1 COSHH assessments

- How: Review of documents.

- Who by: Health and safety lead.

- Reported to: Health, safety and security forum.

- Frequency: Annually.

7.2 Guidance is implemented

- How: During workplace health and safety inspections.

- Who by: Managers and Safety team.

- Reported to: Health, safety and security forum.

- Frequency: Annually.

7.3 Suitability of arrangements

- How: Reviewing incidents involving contact with hazardous substances.

- Who by: Safety team.

- Reported to: Health, safety and security forum.

- Frequency: As incidents are reported.

8 Equality impact assessment screening

To access the equality impact assessment for this policy, please email rdash.equalityanddiversity@nhs.net to request the document.

8.1 Privacy, dignity and respect

The NHS constitution states that all patients should feel that their privacy and dignity are respected while they are in hospital. High Quality Care for All (2008), Lord Darzi’s review of the NHS, identifies the need to organise care around the individual, ‘not just clinically but in terms of dignity and respect’.

As a consequence the trust is required to articulate its intent to deliver care with privacy and dignity that treats all service users with respect. Therefore, all procedural documents will be considered, if relevant, to reflect the requirement to treat everyone with privacy, dignity and respect, (when appropriate this should also include how same sex accommodation is provided).

8.1.1 How this will be met

No issues have been identified in relation to this policy.

8.2 Mental Capacity Act 2005

Central to any aspect of care delivered to adults and young people aged 16 years or over will be the consideration of the individuals’ capacity to participate in the decision-making process. Consequently, no intervention should be carried out without either the individual’s informed consent, or the powers included in a legal framework, or by order of the court.

Therefore, the trust is required to make sure that all employees working with individuals who use our service are familiar with the provisions within the Mental Capacity Act (2005). For this reason all procedural documents will be considered, if relevant to reflect the provisions of the Mental Capacity Act (2005) to ensure that the rights of individual are protected and they are supported to make their own decisions where possible and that any decisions made on their behalf when they lack capacity are made in their best interests and least restrictive of their rights and freedoms.

8.2.1 How this will be met

All individuals involved in the implementation of this policy should do so in accordance with the principles of the Mental Capacity Act (2005).

9 Links to any associated documents

10 References

- The Control of Substances Hazardous to Health Regulations 2002 Approved Code of Practice and guidance. L5 (sixth edition), HSE Books (opens in new window)

- Control of Substance Hazardous to Health (COSHH). HSE guidance (opens in new window)

- EH40/2005 Workplace Exposure Limits, Containing the list of workplace exposure limits for use with the Control of Substances Hazardous to Health Regulations 2002 (as amended). (fourth edition) January 2020. (opens in new window)

- The Management of Health and Safety at Work Regulations 1999 (opens in new window)

- Workplace (Health, Safety and Welfare) Regulations 1992 (opens in new window)

- The European Regulation (EC) No 1272/2008 on classification, labelling and packaging of substances and mixtures (opens in new window)

- REACH (Registration, Evaluation, Authorisation and restriction of Chemicals). HSE guidance. (opens in new window)

- Legionnaires’ disease. The control of legionella bacteria in water systems, Approved code of practice. L8 (fourth edition) 2013. (opens in new window)

11 Appendices

11.1 Appendix A Principles of good practising for the control of exposure to substances hazardous to health

- Design and operate processes and activities to minimise emission, release and spread of substances hazardous to health.

- Take into account all relevant routes of exposure, inhalation, skin absorption and ingestion, when developing control measures.

- Control exposure by measures that are proportionate to health risk.

- Choose the most effective and reliable control options which minimise the escape and spread of substances hazardous to health.

- Where adequate control of exposure cannot be achieved by other means in combination with other control measures suitable personal protective equipment should be provided.

- Regularly check and review all elements of control measures for their continuing effectiveness.

- Inform and train all employees on the hazards and risks from the substances with which they work and the use of control measures developed to minimise risks.

- Ensure the introduction of control measures does not increase the overall risk to health and safety.

11.2 Appendix B COSHH risk assessment

11.3 Appendix C Using generic assessments

Generic or “family group” assessments are available for all materials commonly used in hospitals and available from many different suppliers. Materials such as anaesthetic gases, general-purpose cleaners, sterilising agents, solvents or solvent based paints, etc although supplied under many different trade names do, in numerous cases, pose very similar risk to health. Generic assessments can therefore be used to cover “family groups” of similar materials.

Using generic assessments within a department can drastically reduce the number of assessments required and also allows staff to become familiar with a general set of precautions to be followed. Generic assessments may also be used as an interim measure, whilst awaiting a specific assessment for each product.

11.3.1 Allocation of materials into generic categories

- Obtain material safety data sheet for material to be allocated into a generic category.

- Identify the “keyword” or “family group” for the material, for example, anaesthetic, disinfectant, etc.

- Identify the constituents of the material.

- Place the material into the correct category, depending on keyword and contents.

| Generic category | Keyword | Constituents |

|---|---|---|

| Anaesthetic gas | Anaesthetic | Nitrous Oxide |

| Disinfectant | Disinfectant | Phenol |

| Sterilising agent | Steriliser | Glutaraldehyde |

| Paint (solvent) | Paint | White spirit |

- Check any workplace exposure standards from the data sheet against those quoted on the generic. The data sheet standard must have a higher or equal numeric value to the generic assessment for the generic to be applicable.

- Check the assessment activity to make sure that it is suitable for the work to be carried out. If, for example, the material is to be sprayed then there should be a specific activity “SPRAY”.

- If 5 and 6 above match then the generic assessment can be used.

Document control

- Version: 8.1.

- Unique reference number: 210.

- Approved by: Corporate policies approval group.

- Date approved: 11 January 2024.

- Name of originator or author: Health and safety lead.

- Name of responsible individual: Executive director of nursing and allied health professionals.

- Date issued: 12 January 2024.

- Review date: 30 September 2026.

- Target audience: All trust employees, contractors and volunteers.

- Description of changes: 3 year review.

Page last reviewed: November 18, 2024

Next review due: November 18, 2025

Problem with this page?

Please tell us about any problems you have found with this web page.